Rice houses,Rice masonry

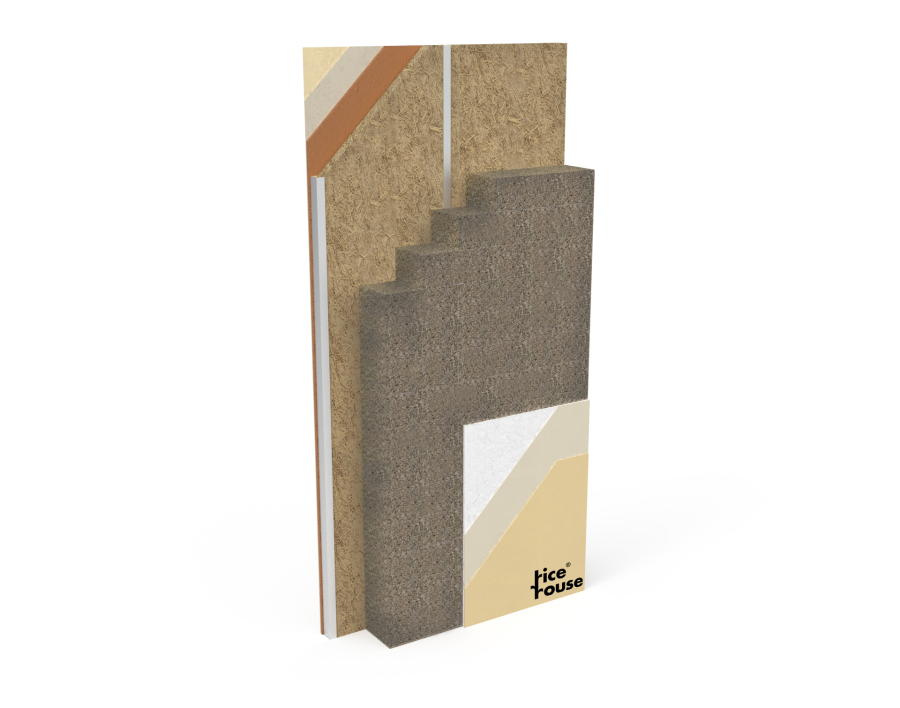

Building system for perimeter mansory with rice husk block

Is the first masonry system manufactured on site from the food by-product of the world's most widely used and consumed cereal, rice. The straw, husk and chaff of the rice are the inert and insulating materials that make up the stratigraphy, from the prefabricated blocks to the insulating panels to the plaster. A second raw material that is not only natural, ecological and sustainable but capable of fulfilling traditional building and energy requirements in a few simple elements that streamline the stratigraphy and improve laying times and ease, guaranteeing exceptional health and comfort performance.

Masonry built using insulating blocks of rice husk, straw and natural cement prompt (RH-B). the system provides lime-based bedding mortar for laying the blocks. The finish on the external side consists of a first layer of lime-lake base plaster (RH100), skimming plaster (RH210) and lime-pula finishing plaster (RH220); internally it consists of a drywall made of aluminium profiles to house the plant systems and a layer of further insulation made of semi-rigid rice-straw insulating panels (RH50) and a closing layer of raw earth panels, clay-lake base plaster (RH400) and finishing plaster in clay-lake-rice-pulp (RH410).